8. NK Discovers Carpets – 1

7. Writing On Shekhawati Murals

May 28, 2020

9. NK Discovers Carpets – 2

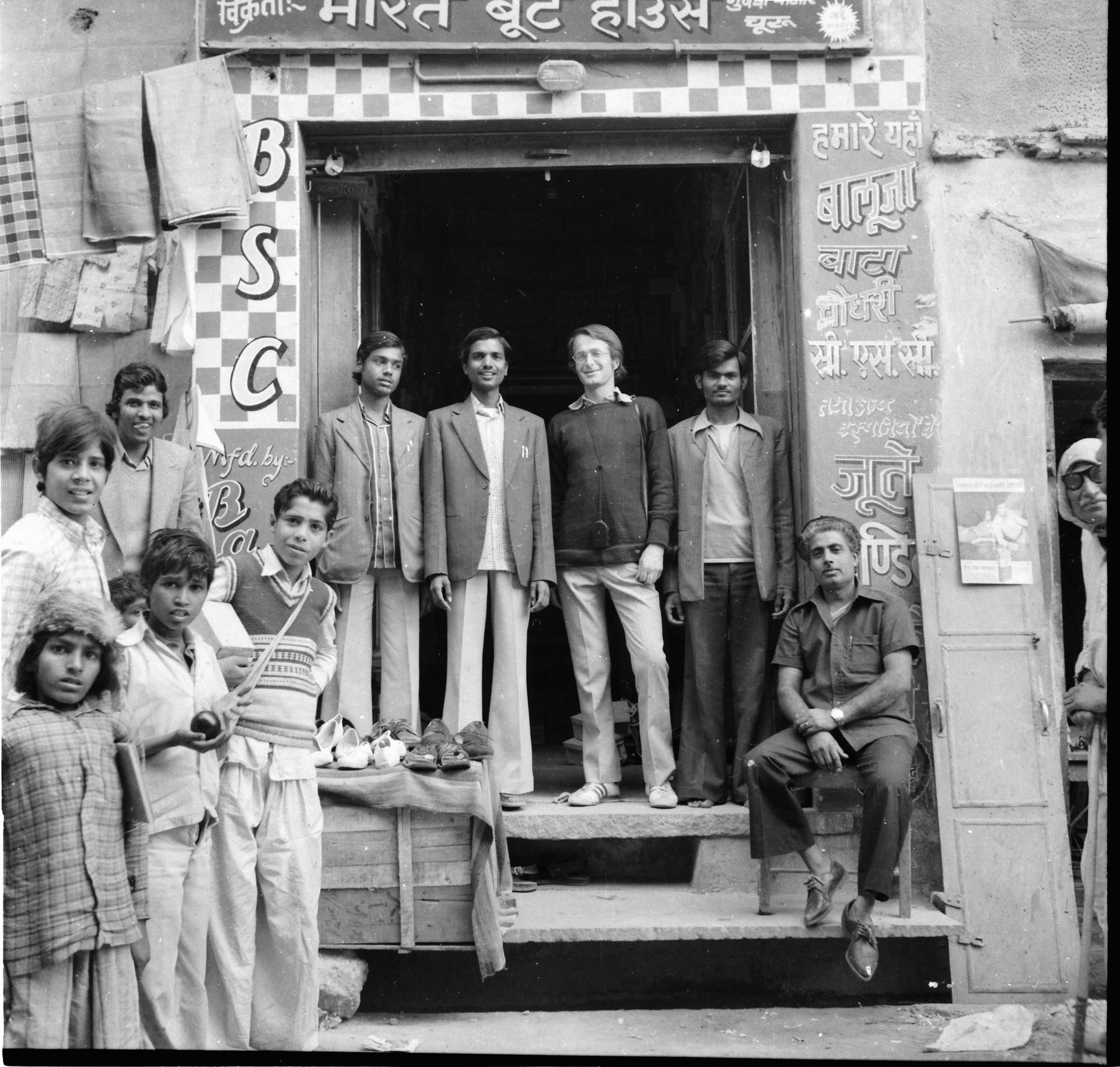

June 11, 2020P rior to 1984, Commonwealth citizens like me required no visas to enter other Commonwealth countries. Arriving in Churu on that new, blue bike in late 1978, I remained there on and off until 1981. From the time we met, Nand Kishor Chaudhary – NK - had been helping to run the family shoe shop, Bharat Boot House in Gudri Bazaar, which became my postal address, but he was always looking for a better business opportunity.

In early March 1979, returning from a tour, I found NK full of carpet plans, partly inspired by another man, Pathakji, who briefly contemplated a business partnership. Occasionally, Pathakji dropped by at my room and the following year, talking of his reluctance, he said 'NK is bound to fail'. By then, I felt strongly that, given his commitment, he ought to succeed. Pathakji continued: 'I gave him the idea, taught him about the carpet industry, but my family opposed a partnership because neither wool nor looms were available in Churu.' 'But why did you encourage him if he was bound to fail, then discourage him now he begins to succeed? Were you honest then or now?' He switched the subject to a recent Algerian earthquake...

So NK embarked on the project with his brother. Spending much time at his shop and house, I was well-placed to record progress. He had done his homework: Rajasthan produced 45% of India's wool but held only 7000 of her 50,000 looms. Jaipur, Rajasthan's capital 200 km away, was an established carpet centre where wooden looms, cotton thread and the dyed semi-worsted wool used in carpet making were readily available. However, the only place in Rajasthan famous for manufacturing quality carpets was Bikaner, the weavers being prisoners in the city's jail. There was demand: Jaipur's exporters had booked up production for two years ahead. Foreign competition came from the Middle East, including Turkey and Iran, where labour costs were rising. Iran, synonymous with fine carpets, was in political disarray. India offered lower prices and stability.

Rajasthan's government had sponsored carpet-weaving centre in Churu, where a master from Benares held two-month courses for local boys. They had the added encouragment of a small attendance stipend. Failing to inspire local interest the centre closed, leaving trained boys and a master in need of employment. NK's first move was to acquire a government loan. Luckily, the office involved lay in the fort, conveniently situated between the shop and his house. Once that was agreed, he approached the master and some of his trained boys, then ordered a pair of looms.

The nucleus of the house, shared with another family, stood behind an open, unpaved walled courtyard, a door opening to the road. A door led to another block, including a ground-floor baithak (sitting room cum office) with a smaller unpaved court in front. Here he planned to put his looms; it also gave onto the road, giving the weavers and other visitors access without invading the privacy of the house. There were caste issues which NK was compelled to respect. Even I, as a meat-eating mlechha, was polluting, which explained why NK, who had no time for these things, washed my plates himself. The weavers, of various castes, carefully ate amongst their caste brothers and there was a separate pot of water for each group.

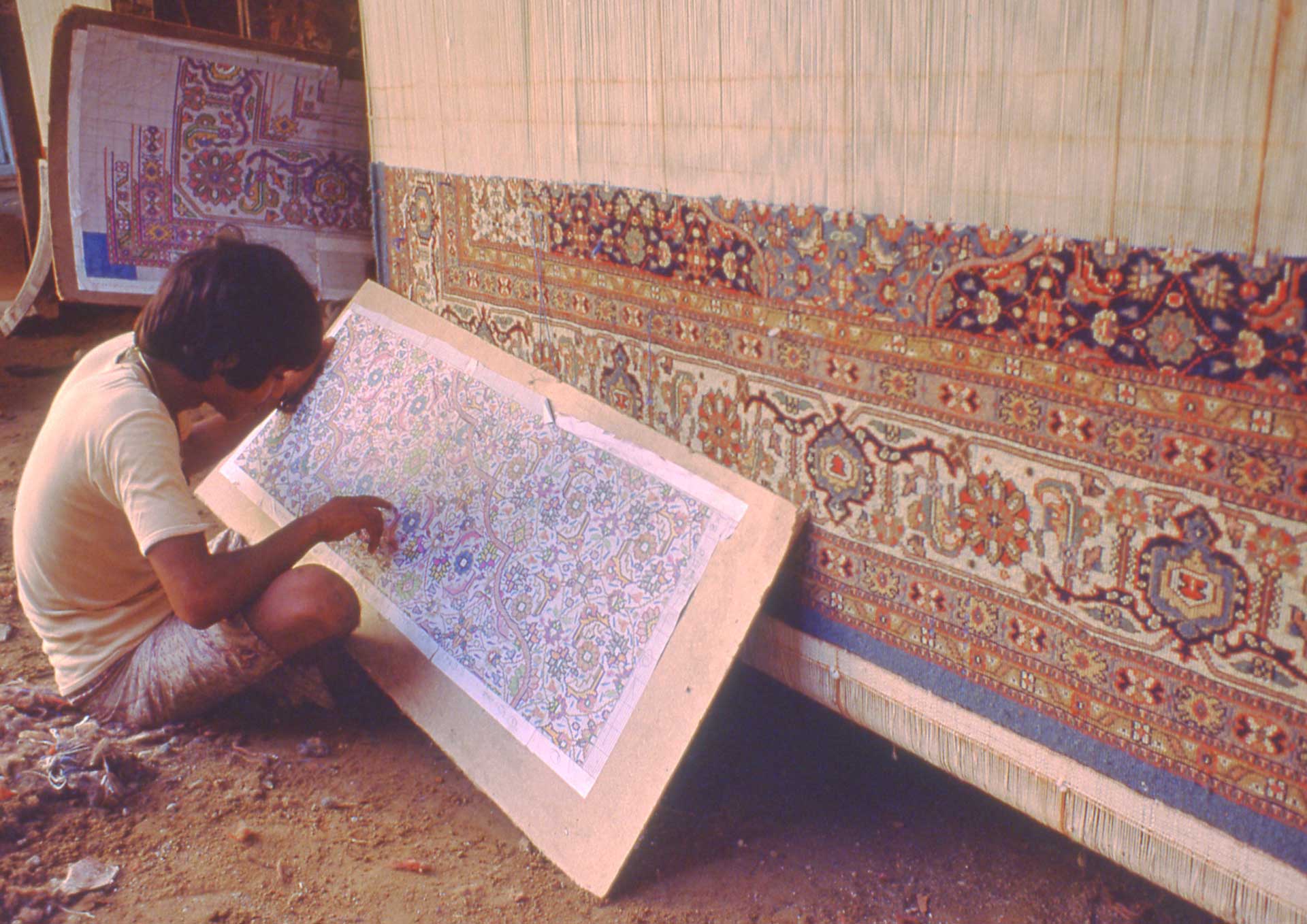

Initially NK had to work for established exporters, who provided wool, thread and maps made on graph paper of the detailed designs they required, derived from popular Persian-style patterns. They paid him a fixed rate per square foot on finished carpets, reducing the sum for every flaw in quality. NK, like other producers, complained that these cuts were excessive; perhaps they were, but strict quality control was important. Known as the thekedar system, this was how every manufacturer started. NK soon dreamed of handling his own exports. The final touches, separation, washing and clipping, took place in Jaipur.

In April, the first two looms, one 13ft, the other 15ft wide, were set up. Then came the 'tani-bani': supervised by the master, the white cotton strings of the tani (warp) being looped and set out on the ground before being placed on the loom. Four boys worked on each loom, knotting from the margin inwards to create a pair of six foot by four foot rugs. These, woven in one piece, would be separated professionally in Jaipur.

The boys were confronted by a double row of warp strings – front and back - beyond which a map-reader crouched, singing out the required colour and number of knots they must tie onto the strings of the warp. Behind each knotter hung a row of hanks of appropriately-coloured wools. On the reader's command, he pulled out the correct colour thread, knotted it then cut it off with a curved knife, churi. Since the two carpets were identical the command applied to all four boys on that loom. When a row of knots was complete two cotton threads of weft – bani – were passed between the warp strings and beaten down with a comb-like panja. Then the back row of warp was pulled forward and the next row began.

Photographing their work or the latest carpets, I got to know most of the knotters. Both Hindus and Muslims, they came from different backgrounds: unsurprisingly, the best workers were weavers by caste. After several months there were problems with the master. Some boys thought he was more interested in them than the carpets. Afterwards, we went to a nearby town to meet one possible replacement, who had spent a long murder sentence making carpets in Bikaner Jail. Unfortunately he didn't know how to prepare the tani-bani. Other masters came and went. Meanwhile, NK was becoming increasingly knowledgable about the techniques of carpet production. In September he took delivery of five more looms, constructing and roofing over another court to house them.

Responding to the demand for illustrated articles for India's many English-language publication, I wrote a piece based on NK's carpet experience, which was published in the design magazine, 'Inside-Outside', the following year.